Targeting safety training with wearable technology using biofeedback and data insights

Coca Cola Amatil

Case Study

General information

With approximately 12,000 employees and operating 75 production and warehouse facilities, Coca Cola Amatil, one of the largest bottlers and distributors of non-alcoholic and alcoholic ready-to-drink beverages in the Asia Pacific region, saw the opportunity to use the Soter technology to boost their safety and pinpoint areas of risk as a proactive approach to decrease potential injuries.

Having a large, distributed workforce, they were looking for opportunities to provide manual handling training that was consistent, autonomous and created real behavioural change. The Soter technology provided the results they were after and fit the criteria for their business.

Choosing to use the SoterCoach solution in their high-risk areas; manufacturing, warehousing and distribution, engaging both male and female employees as well as first time users and sceptics of wearable tech.

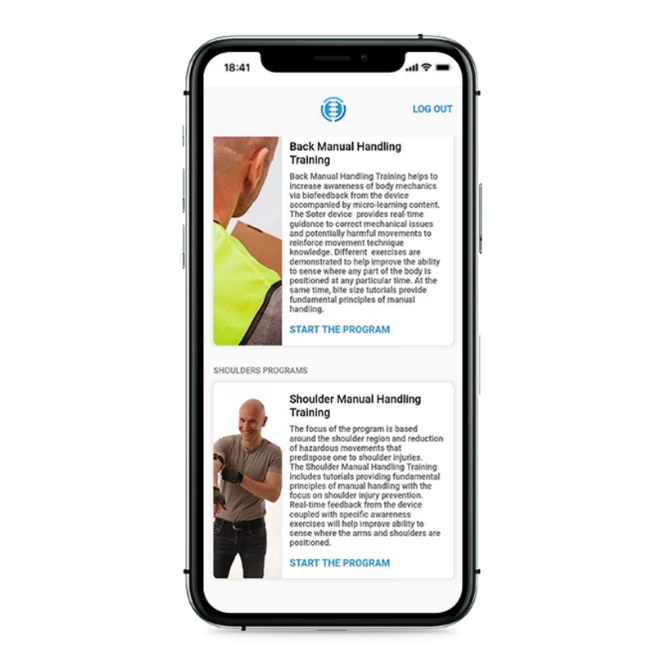

SoterCoach included the use of a downloadable app onto the worker’s personal smartphone. The app provided individual result data along with the option to complete a 10-day manual handling training program. The program was completed on-the-job and consisted of microlearning 3-5 minute daily tutorials.

-

The device was collected from a central hub in the safety area at the start of a shift, scanned out and clipped to the shirt/vest.

-

Throughout the day the sensor provided real-time audible and vibration biofeedback alerting the workers of any hazardous movements they made. The individualized notifications optimize training and health, assisting injury prevention and overuse issues, creating sustainable change through real-time training.

-

At the end of the shift, the device was returned to the hub, rescanned, with the option to view personal data for the shift and collect virtual badges in the gamified environment, all to drive improvement.

The ‘Positive Content’ rating was 100% with workers saying:

“I believe the device is very informative on the information you can receive about taking care of your body and ways to improve day to day actions while working in a manual handling environment. The program has made me more aware of my body position and am more aware when lifting and twisting to ensure I do it correctly”

"The manual handling data and insights provided by Soter identified the key manual handling risk within our business, how this risk differs across roles and individuals and how we compare when benchmarked with our organisational peers"

The Soter device measures and captures the hazardous movements that lead to injury, the leading bottler saw an overall 31% reduction of hazardous movements across all risk groups after using the wearable solutions.

Breakdown of hazardous movements by type, hour, ratios, improvements and peaks in risk were all captured. The data-based insights allowed targeting safety training to be implemented.

The management dashboard provided the company with objective data and gave insight to numerous areas of risk that assisted to tailor ongoing training based on the individuals risk profiles and to better understand workloads and suitability for roles.

Benchmarking against global peers and within departments across different sites helped to identify where the risks were and has enabled a tailored approach to their in-house coaching to better support their employees manual handling training.

Using technology to assist injury prevention with the ability to deploy and scale with minimal invasion provided a solution that not only allowed on-the-job autonomous learning for the workers, reducing down time, but objective insight for management. The large bottler has seen that reducing the number of hazardous movements that can lead to injury can significantly reduce their injury management costs and lost time due to manual handling injuries.

More Success Stories

-

Travis Perkins

Soter Analytics helps UK’s largest building merchant to reduce manual handling injuries by 55%

-

Giant Eagle Supermarkets

Wearable devices help the 34,000-employee retailer reduce risk of injury by 31%

-

United Farmers of Alberta

United Farmers of Alberta reduced ergonomic injuries by 86% with behavior changing wearables

-

Wincanton

Wincanton uses Soter AI-ergonomic sensors resulting in 250 days of no lost-time injuries

Book a Free Online Demo

We'll give you an overview of Soter Solutions, provide examples of use cases, show you the dashboard and reporting, and talk through the basics of a good implementation. As the result, you'll see how your organization can:

-

REDUCE INJURIES

Get up to 86% of reduction in back & shoulder ergonomic injuries

-

DRIVE-DOWN CLAIMS COSTS

Achieve up to 67% of reduction in workers compensation costs

-

IMPROVE PRODUCTIVITY

Ensure smooth operations and reduce employee turnover

-

BOOST ROI

Earn over 250% ROI when partnering with Soter Analytics