Wearable devices help the 34,000-employee retailer reduce risk of injury by 31%

Giant Eagle

Case Study

General information

According to the US Bureau of Labor Statistics 2018 Survey of Occupational Injuries and Illnesses, injuries in the retail and warehousing/distribution sector are in the top 10 most dangerous occupations for workers, with sprains, strains, and tears being some of the most common afflictions.

After a successful initial 3-month trial in 2018 that showcased immediate results in reduction of the hazardous movements that lead to injury, Giant Eagle continued to collaborate with Soter Analytics to roll out their SoterCoach solution, a fully autonomous product specifically designed for large facilities.

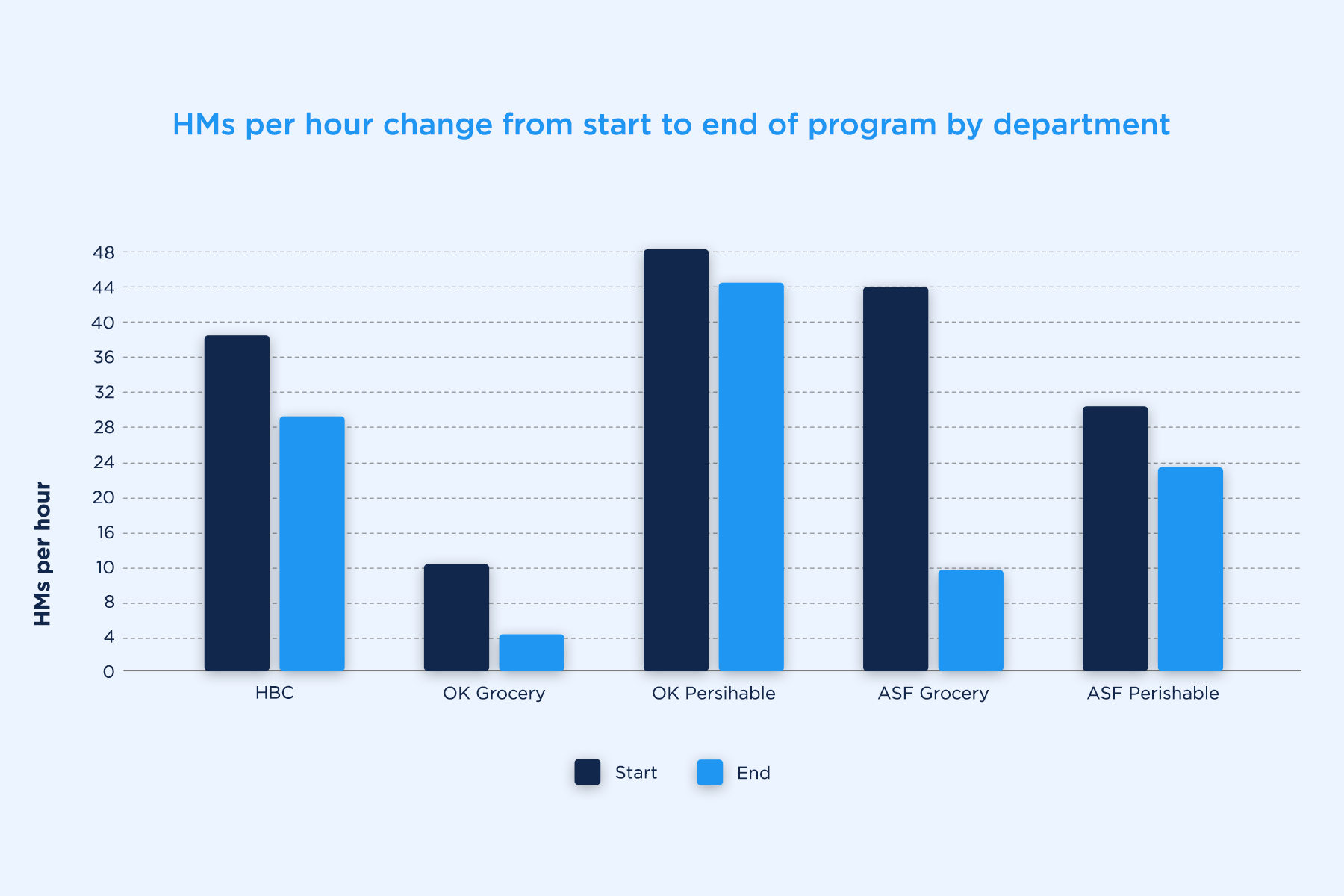

The Soter device measures and captures up to 8 different hazardous movements that lead to injury and Giant Eagle had an overall reduction of 31% after using the Clip&Go solution.

Mr. Shawn Rush, Sr. Director, Environmental, Health & Safety Giant Eagle says, “The solution accurately detects and provides warnings for hazardous movements that have high potential to cause injury. As a result, we’ve seen the number of at-risk postures and movements cut roughly in half for the Team Members involved in the process”.

.jpg)

Poor Technique:

- Low Intensity Lifting - 33%

- High Intensity Lifting - 28%

Lifting with poor technique can be described as making end range bending movements while performing working tasks. End range bending places muscles at full stretch, which leads to temporary muscle weakness or ‘deactivation’. As a result, the spine is not adequately protected by its muscles, potentially making it unstable.

When describing intensity, the technology does not measure weight of objects but rather the intensity of a movement – the movement is defined as highly intensive when for different reasons, the person finds it physically difficult to perform. In many cases it contributes to working with the high load. If a large load is carried, even a small amount of bending can lead to injury, since fibres of the discs are much less tolerant to load at this position.

Jerky and fast movements are also defined as high intensity. Fast extension movements create a larger window during which the spine is exposed to instability and injury because of lack of muscle forces. Also, physical conditions such as fatigue or disease can dramatically lessen the weight that can be lifted safely at any one time, and this may also be measured as high intensity.

Estimates are that Giant Eagle will have more than 8,000 hours of worker collected data every month and all this will be presented in an easy-to-comprehend format on the Soter Dashboard allowing professionals to move away from spending time trying to locate risks and instead use the time to create solutions.

At Giant Eagle, the management dashboard provided objective data and gave insight to all areas of the business allowing the company to spotlight areas within its retail support centers that were at most risk and provide any necessary controls to limit exposure.

Using technology to assist injury prevention with the ability to deploy and scale with minimal invasion provided Giant Eagle with a solution that not only allowed in-situ autonomous learning for its Team Members, but objective insight for management. After producing very positive results, the SoterCoach solution is now being rolled out across multiple Giant Eagle facilities with the focus on new Team Members using it to learn best-practice manual handling techniques when commencing their employment with Giant Eagle.

More Success Stories

-

Wincanton

Wincanton uses Soter AI-ergonomic sensors resulting in 250 days of no lost-time injuries

-

United Farmers of Alberta

United Farmers of Alberta reduced ergonomic injuries by 86% with behavior changing wearables

-

Travis Perkins

Soter Analytics helps UK’s largest building merchant to reduce manual handling injuries by 55%

-

Book a Free Online Demo

We'll give you an overview of Soter Solutions, provide examples of use cases, show you the dashboard and reporting, and talk through the basics of a good implementation. As the result, you'll see how your organization can:

-

REDUCE INJURIES

Get up to 86% of reduction in back & shoulder ergonomic injuries

-

DRIVE-DOWN CLAIMS COSTS

Achieve up to 67% of reduction in workers compensation costs

-

IMPROVE PRODUCTIVITY

Ensure smooth operations and reduce employee turnover

-

BOOST ROI

Earn over 250% ROI when partnering with Soter Analytics