Kenco uses SoterCoach wearable technology to proactively prevent injuries

Kenco Logistics

Case Study

General information

To “demonstrate courage, commitment, and compassion” is one of Kenco’s Guiding Principles, and people are at the core of these principles. Thus, building a culture of safety is a high priority at Kenco warehouses.

Seeking to empower their people and customers through connected solutions and leveraging digital transformation to achieve results, Kenco is proactive about scouting the right technologies to enhance the working environment of their associates with innovative and safety-focused products. Carefully compared with other wearable technologies on market for musculoskeletal safety, the SoterCoach program was chosen as the best fit for their organization.

Kenco piloted the technology with several different job functions in one of their most physically demanding warehouses, with a focus mainly on pickers.

- Associate picks up the device from a central safety area at the start of a shift, scans it out and clips it to their shirt/vest.

- Throughout the day the sensor provides real-time audible and vibration biofeedback alerting associates of any hazardous movements they make. The individualized notifications optimize training and health, preventing injury and overuse issues, creating sustainable change through real-time training.

- At the end of the shift, the user returns the device to the safety area, rescanning it with the option to view their personal data for the shift, collect virtual badges in the gamified environment, all to drive improvement.

"Nobody likes back pain, but proper lifting is a habit that many new associates have not yet developed. The Soter device gently yet persistently raises the level of awareness, building a good incentive to use better body mechanics. The results of the Soter pilot program showed us that this product is an effective tool to reduce incorrect lifting, which can lead to fatigue, soreness, and even injury"

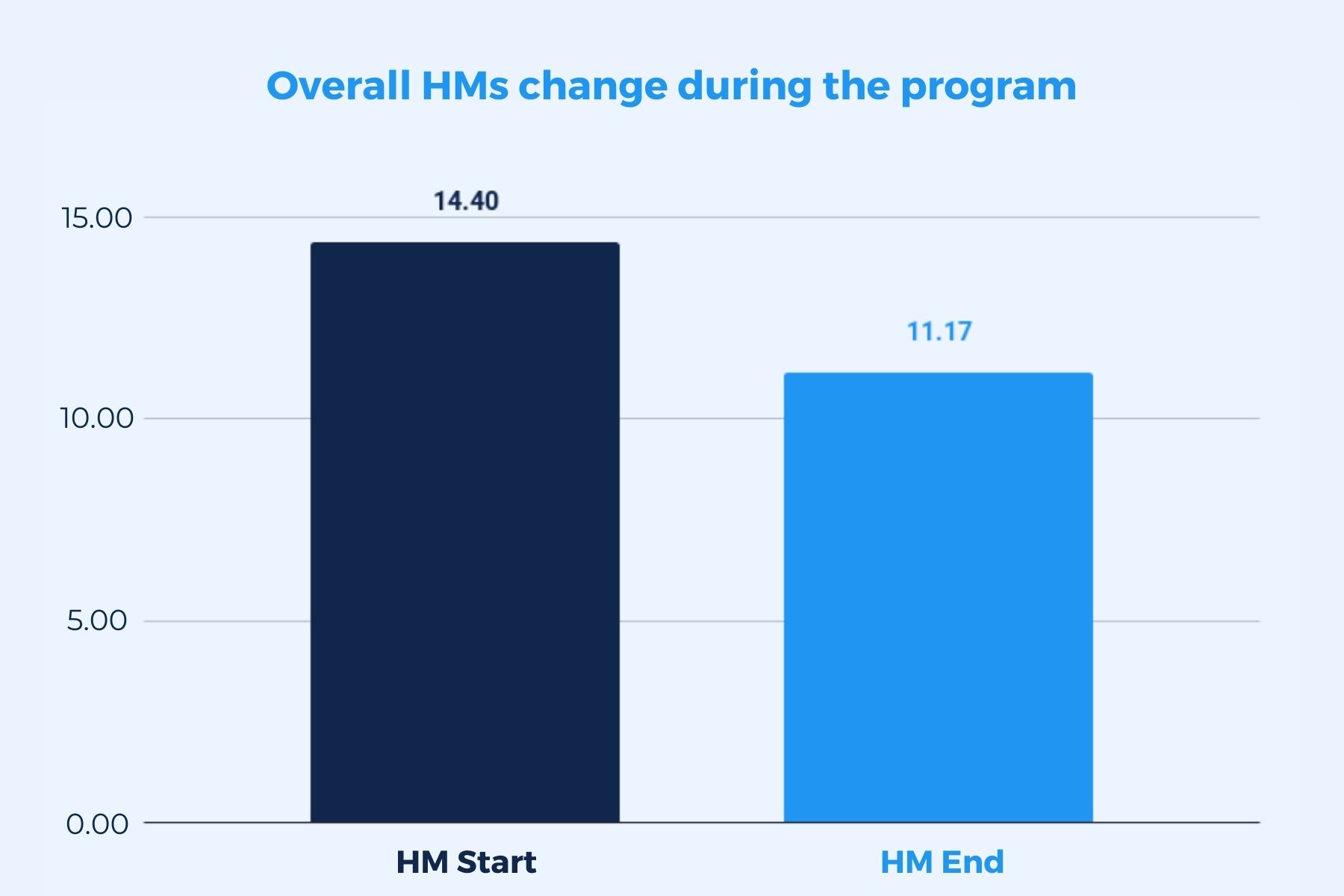

Kenco saw a 22% reduction of hazardous movements.

The Soter device measures and captures the hazardous movements that lead to injury. Using AI and machine learning, the device alerts the associate of exposures to known risk factors for musculoskeletal disorders that increase their risk of injury.

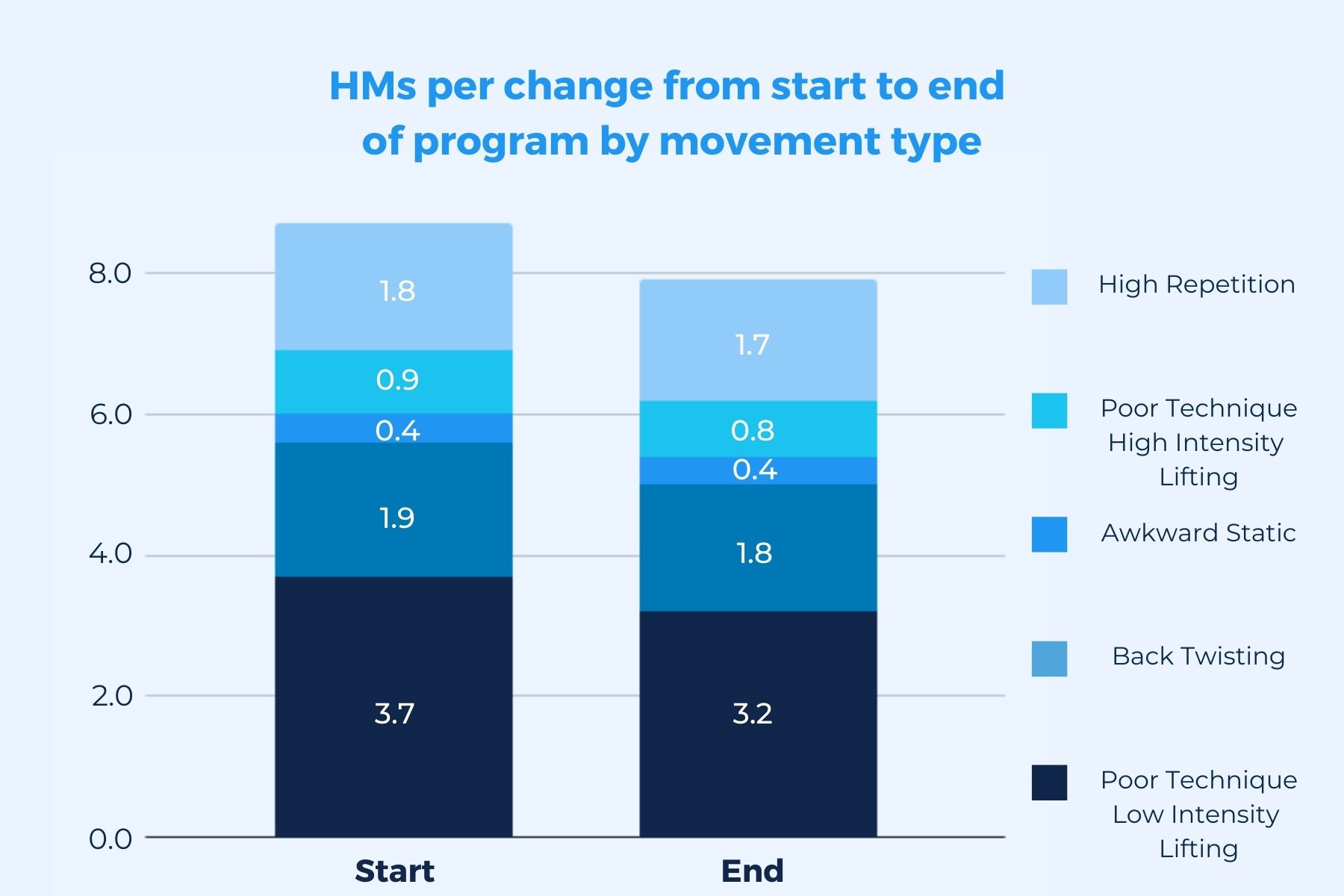

The device collected improvement metrics on hazardous movements.

Breakdown of hazardous movements by type, hour, ratios, improvements and peaks in risk were all captured. The data-based insights allowed targeting safety training to be implemented.

More Success Stories

-

Travis Perkins

Soter Analytics helps UK’s largest building merchant to reduce manual handling injuries by 55%

-

Giant Eagle Supermarkets

Wearable devices help the 34,000-employee retailer reduce risk of injury by 31%

-

United Farmers of Alberta

United Farmers of Alberta reduced ergonomic injuries by 86% with behavior changing wearables

-

Wincanton

Wincanton uses Soter AI-ergonomic sensors resulting in 250 days of no lost-time injuries

Book a Free Online Demo

We'll give you an overview of Soter Solutions, provide examples of use cases, show you the dashboard and reporting, and talk through the basics of a good implementation. As the result, you'll see how your organization can:

-

REDUCE INJURIES

Get up to 86% of reduction in back & shoulder ergonomic injuries

-

DRIVE-DOWN CLAIMS COSTS

Achieve up to 67% of reduction in workers compensation costs

-

IMPROVE PRODUCTIVITY

Ensure smooth operations and reduce employee turnover

-

BOOST ROI

Earn over 250% ROI when partnering with Soter Analytics