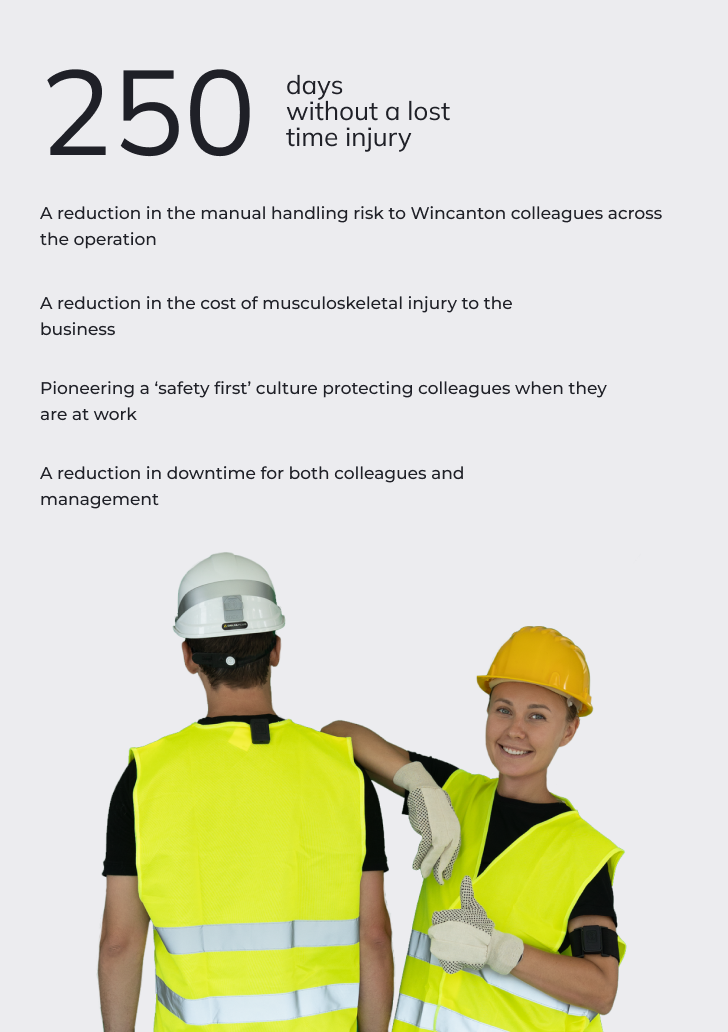

Wincanton uses Soter AI-ergonomic sensors resulting in 250 days of no lost time injuries

Wincanton

Case Study

General information

The team took advantage of using the Soter wearable devices, and the data they provide, to reduce injury risk and associated costs, create a positive, ‘safe movement’ culture, and establish new ways of engaging their workers in safety.

Wincanton recognized an opportunity to improve and drive innovation in their safety processes and the SoterCoach program filled this, providing scalable manual handling safety training and continuous monitoring of safety required for large, dispersed environments.

The company takes a collaborative approach to building a team environment that supports innovation, develops fit-for-purpose and sustainable solutions, and delivers results. They assess hazards effectively, make informed, intelligent plans and prepare for all eventualities to keep everyone safe.

This contributes to a business that offers people a great place to work and a culture that supports individual and business success.

The Wincanton retail warehouse operation is primarily responsible for the pick, pack and dispatch of household, and other ‘awkward’ products directly to the end customer.

20% of all products ranged and delivered are above 15kgs. These products comprise 19% of the lifts that are performed by colleagues across the operation.

Musculoskeletal activity is the 4th highest hazard within the operation.

As part of their safety processes, Wincanton wanted to be able to give movement training to colleagues whilst on the job so they could learn how they were moving whilst working rather than only in a classroom setting. They needed to find a solution that was personal and allowed workers to oversee their own safety.

Furthermore, new starter adherence was reliant on shift coaches and the large numbers of new starters along with a very large, dispersed site, (around 1 million sq/ft of warehousing split over 4 units on 2 million sq/ft), presented an opportunity to enhance the shift coach’s role with use of personalized technology.

There was a significant need for formalised continual checking of adherence to manual handling and the challenge was to find a solution that:

-

Was scalable;

-

Gave workers the individual training they needed to move safely - on the job;

-

Incited permanent behavioural change;

-

Provided formalised monitoring, coaching and support to assess compliance with Manual handling training for: new starters, colleagues returning after an incident or injury, colleagues recommencing work after a performance management issue related to manual handling compliance, all colleagues at random points across the year.

These sensors were issued to each colleague, and linked to their performance, using a tablet PC in the SoterCoach docking hub, which also charged the units (each has a 30-day lifespan before requiring a full recharge).

The behavioural change aspect of the sensors’ real-time biofeedback encouraged each worker to internally learn new and correct movement patterns, altering neuromuscular pathways resulting in permanent change.

"Given the size of the site, SoterCoach seemed like an ideal ‘intervention’ tool to give colleagues feedback on how they were performing their roles and allow them to ‘self-coach’ their own behaviour"

A collection of hand-picked colleagues and safety professionals across the operation were chosen to introduce the technology to a wider audience. This allowed them to speak from a position of experience to colleagues about how it worked, the information they would receive and how it had personally helped them across the 2 weeks.

Typical colleague concerns when introducing technology and devices such as SoterCoach includes:

- Using them as a GPS tracker to see where they were on site;

- Tracking them for performance management;

- Using the data to manage those not improving their results.

To overcome this, Wincanton worked with Soter to clearly understand the sensors and eliminated the use of words like ‘tracker’ or ‘monitoring’ to remove any uncertainty.

Wincanton used information presentations from Soter to explain what applications the technology contained and how the devices were there to support the workers, giving ‘them’, information and coaching on how to move safely.

They used examples and compared the devices to a FitBit or Apple Watch that would give them not only data on how they are moving but teach them to move correctly and get to know their body more to stay safe.

The data collected has been used to provide support and retraining to those colleagues in high-risk groups and easily spot areas in the business that are unsafe and need to be reviewed.

One colleague discussed how personal the technology was to them and indicated that it was a good sign of how Wincanton invested in technology to make their job safer.

Colleagues were unanimous in how easy it was to use and how straightforward and unobtrusive the devices were.

"We have been really pleased and surprised to find colleagues taking it to heart and doing their best to reduce the vibration and haptic feedback alerts that increase awareness of their unsafe movement postures. Their considerations have been along the lines of “I can choose to ignore the warnings, but they are there to give me information to help keep me safe so why would I?”. Bringing this technology into our teams has empowered our workers to tell us about their safety"

Wincanton will continue to use the devices, implementing the program into safety processes and have colleagues participate every six months to sustain their improved manual handling postures and stay injury-free.

“It’s been a fantastic success and what really crystallised it for me was when the sites passed the 250 days without a lost-time injury”

More Success Stories

-

Travis Perkins

Soter Analytics helps UK’s largest building merchant to reduce manual handling injuries by 55%

-

Kenco Logistics

Kenco uses SoterCoach wearable technology to proactively prevent injuries

-

Giant Eagle Supermarkets

Wearable devices help the 34,000-employee retailer reduce risk of injury by 31%

-

United Farmers of Alberta

United Farmers of Alberta reduced ergonomic injuries by 86% with behavior changing wearables

Book a Free Online Demo

We'll give you an overview of Soter Solutions, provide examples of use cases, show you the dashboard and reporting, and talk through the basics of a good implementation. As the result, you'll see how your organization can:

-

REDUCE INJURIES

Get up to 86% of reduction in back & shoulder ergonomic injuries

-

DRIVE-DOWN CLAIMS COSTS

Achieve up to 67% of reduction in workers compensation costs

-

IMPROVE PRODUCTIVITY

Ensure smooth operations and reduce employee turnover

-

BOOST ROI

Earn over 250% ROI when partnering with Soter Analytics