Warehouses are filled with risks and hazards that could potentially cause significant harm to workers. According to the Bureau of Labor Statistics in the US there are on average 16 fatalities in warehouses every year with a reported injury rate as high as 5%. It is no surprise then that warehouse safety is always a top priority for warehouse managers. It is imperative to ensure the safety of employees while they are at work not only to protect them but also to keep business costs down, maximize productivity and maintain a good reputation. In this article, we examine the key areas of concern and some best practices for maintaining warehouse safety. We also explore new advances in technology and how these innovations can drive a reduction in injury rates.

Key Areas Of Concern For Warehouse Safety

Warehouses process and store stock prior to shipping to customers. The large volumes of stock must be carefully managed right through from receipt and shelving to picking and despatch. As a result, warehouses rely on a strong team to manage these physically demanding tasks. The environment can be fraught with hazards and risks resulting from these key areas of concern: vehicles, slips and trips, ergonomics and manual handling, working at heights, fire safety, moving or falling objects and hazardous chemicals. It is important to gain a thorough understanding of all the potential risks to ensure the safety of employees.

Vehicles

To move stock around, warehouses employ a number of vehicles from forklifts to vans to trucks. These vehicles move about the warehouse in areas that are often shared by employees. This results in an increased likelihood of injuries as a result of collisions, improper training or vehicle failures.

Slips and Trips

Slips and trips are the most common cause of workplace injuries. Warehouses are filled with equipment and stock that can easily clog aisles and lead to an increased risk of slipping or tripping.

Ergonomics

Incorrect movement techniques account for as much as 20% of non-fatal injuries in the workplace. In a warehouse environment, manual handling is unavoidable and as a result, injuries stemming from poor ergonomics are extremely common. Workers who are frequently required to bend, lift or twist are exposed to a higher risk of musculoskeletal injuries. Due to the nature of the working environment, the warehouse industry has a much higher rate of musculoskeletal injuries compared to others.

Heights

With shelves stacked high, it is commonplace for warehouse team members to be required to work at heights. However, working at heights can be extremely hazardous and lead to many workplace injuries. Falling injuries account for more than a quarter of all workplace fatalities on average.

Fire Safety

In any workplace, fire safety is a potential hazard. As a result, it is now a globally recognized standard to incorporate processes and equipment like fire alarms and extinguishers, sprinklers, fire evacuation procedures and employee training.

Falling Objects

Warehouse shelves can often be stacked from floor to ceiling with heavy boxes. Thus, it is not uncommon for objects to move about or fall unexpectedly. Falling or moving objects can be extremely dangerous and result in approximately one third of all workplace fatalities in warehouses.

Hazardous Chemicals

Even in warehouses not primarily involved in the storing and shipping of chemicals, workers are exposed to potentially hazardous chemicals such as cleaning products or fuel and oil for warehouse machinery. As a result, chemical spills can lead to serious workplace injuries in the warehouse.

Warehouse Safety Best Practices

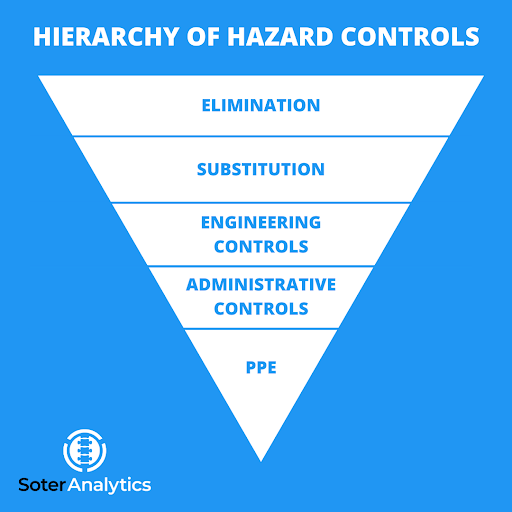

To minimize the risk of injury and foster a safe working environment in the warehouse, many organizations spend lots of money investing in solutions. As a standard, warehouses will employ a workplace health and safety officer or manager to conduct a thorough risk assessment and implement controls to reduce the risks. This is mostly done through following the process outlined in the hierarchy of hazard controls.

The best practices for addressing warehouse safety can be broken down into four categories: training and certification, policies and procedures, workplace design and monitoring and maintaining.

In addressing the key areas of concern in warehouse safety identified above, here are some best practices to reduce risks and keep employees safe.

Training & Certification

Warehouse employees are required to work in a physically demanding environment and operate vehicles and machinery. It is paramount to ensure that they have been adequately trained in both. General workplace health and safety training should be conducted with all new hires and regular refresher courses provided for all staff. Team members operating machinery and vehicles should be trained and appropriately certified in their operation. Specific manual handling training should be provided on a regular basis to foster ergonomic awareness and movement safety.

Policies & Procedures

To support and give guidance to all workers, it is important that policies and standard operating procedures are designed with warehouse safety in mind. Every warehouse should have clear manual handling policies and procedures that implement safe lifting techniques of heavy items, stacking height limits and guides and appropriate weight capacities of shelves and racking. Strict procedures should be in place to keep the warehouse tidy; enforced processes for cleaning spills, removing trip hazards and keeping the aisles clear.

Workplace Design

The physical design of the warehouse and the working environment is another important factor that can support safety and reduce injuries. The warehouse should be equipped with solid steel end barriers to protect against forklift collisions. All workers should be provided with adequate Personal Protective Equipment (PPE) and regular breaks should be scheduled to avoid worker fatigue. Safety signage should be clearly displayed throughout the warehouse and sufficient lighting installed. Racking and shelving systems that are suitable to support the weight of the stock should be established. Providing the appropriately trained team members with access to Mobile Elevating Work Platforms (MEWP) can also help to facilitate safe working at heights.

Monitor & Maintain

All vehicles and machinery, PPE, racking and shelving, barriers, signage, lighting and electronics used in the warehouse should be regularly inspected for faults and maintained to a high standard to ensure worker safety.

Invest in Technology

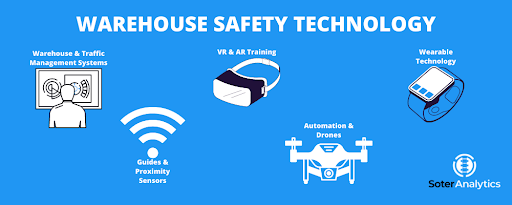

Warehouse safety technology has made leaps and bounds in innovation in recent years. Investing in proven and effective new technology for the warehouse is more than just a passing fad, it is the future of addressing real problems in the workplace to reduce risk and minimize injury. Some of the key developments in warehouse safety technology include advanced warehouse management systems (WMS), traffic management systems, guided forklifts, proximity warning sensors, VR and AR training, automation, drones and wearable technology.

Advanced Warehouse Management & Travel Management Systems

Most warehouses today operate with a basic warehouse management system (WMS) to control and track inventory levels and shipments. In recent years, these systems have developed to integrate with other operational technology, IoT sensors and smart devices. This makes it possible for data to be generated and transmitted to auxiliary equipment such as autonomous robots and transportation systems to assist with hazardous tasks. An advanced WMS can go a long way to not only locate and pick stock more efficiently but also to improve efficiency and limit risk exposure. For larger warehouses, a travel management system can be implemented in conjunction with a WMS to control vehicle movements and avoid collisions through AI technology.

Guided Forklifts & Proximity Warning Sensors

Radio frequency identification (RFID) sensors can be implemented throughout the warehouse to warn workers when they are in close proximity to a potential hazard. These sensors are highly effective at warning distracted or fatigued employees not to wander into the path of vehicles or other equipment. The technology works by employees wearing RFID tags and flagging dangerous areas or equipment with RFID readers.

Sensors can also be used to guide and manage forklifts around the warehouse. Forklifts are an essential piece of equipment used in warehouses to assist with moving stock around the floor. Forklift accidents are extremely common resulting in not only serious injuries but also pallet damage. Thus, it is worth investing in proximity sensors to sound an alarm when forklifts are too close to people or objects. Some of the more advanced forklift guiding systems use low-powered lasers to detect proximity and can even automatically brake or perform emergency operations to steer away from a potential collision.

VR & AR Training

Many new employees in the warehouse are inexperienced. This inexperience can sometimes mean that on-the-job training can be risky leading to accidents and injuries in new hires. But new developments in virtual reality (VR) and augmented reality (AR) are facilitating workers to complete on-the-job training in a completely safe, virtual environment.

This technology supports immersion in a virtual environment (VR) or the incorporation of virtual elements into the real environment (AR). Both VR and AR can be implemented as a powerful tool to facilitate training.

Automation & Drones

Although it is unlikely that robots will ever fully be able to replace humans, it is possible to automate some tasks in the warehouse that are too dangerous for humans. Repetitive movements are one of the most common causes of ergonomic injury. However, robots are excellent at performing repetitive tasks thus reducing the number of repetitive strain injuries. Robots are also capable of working for far longer than humans and working in dangerous spaces.

Drones are one of the key ways in which warehouse processes can be automated. These small, flying robots cannot only easily reach high places to capture barcodes and locations, reducing the need for employees to climb to dangerous heights but they can also work 50% faster than humans.

Wearable Technology

Ergonomic injuries are extremely common in the warehouse with as many as 3% of workers suffering from a back or shoulder injury each year. New advances in ergonomic training using AI-driven wearables with sensors and biofeedback are a great solution for reducing manual handling injuries in the warehouse. Leveraging the power of AI and machine learning, warehouse workers can be coached to self-correct their movements in real-time and avoid ergonomic injuries, stimulating an engaging personalized pathway to behavioral change.

About Soter Analytics

Soter Analytics is a global safety science company producing AI-supported wearable solutions that reduce the risk of ergonomic injuries in the workplace. Soter wearables are widely used in logistics, manufacturing, healthcare and other industries, helping leading companies to prevent up to 55% of back & shoulder musculoskeletal injuries.

To see how Soter Analytics can help you improve safety behaviour, engage employees to self-manage their training and prevent workplace ergonomic injuries, simply Book a FREE Demo today.